Please Call Anytime for an Appointment to Visit Wednesday - Saturday 10:30am - 5pm

Millworks and Sawmill Services

Services that we Offer

Whether you are professional woodcraft designer or that hard-core woodworking "Weekend Warrior", let Sea Island Millworks help you meet your next project needs. We are here to accommodate the very best we can in quality workmanship with our custom milled lumber. Your satisfaction with the product is my priority.

At "The Mill" site we have most southern tree species available for purchase depending upon the resource availability. There are several hardwoods that you can select from slabs to dimensional lumber. Please call ahead of time to ensure we have what you are interested in.

All lumber we offer can be milled to your custom dimensions and particular type of cut. Lumber is "Rough-sawn" either Plain sawn or Quarter sawn. Slab timber, with or without a "live edge", can also be made available.

If you have your own logs, you are more than welcome to bring them out to the sawmill or request a free estimate to have it picked up and brought out to "The Mill". Or even better, arrange to have the portable sawmill brought out to your property and make this a truly unique experience.

Honoring Our Own

We Offer Discounts

Sea Island Millworks is dedicated to honoring all military service members, active and retired, as well, all law enforcement, First Responders and Nursing receive a 10% discount on products and services by Sea Island Millworks. Please Inquire, you deserve it!

Military and First Responders

Physicians, Surgeons and Nursing

Physicians, Surgeons and Nursing

Physicians, Surgeons and Nursing

Products

Dimensional Lumber

Dimensional Lumber

Dimensional Lumber

Rough sawn dimensional Hardwood and Oak boards are great for Barn builds, Patio decking and heavy equipment trailer decking. Hardwood is normally milled at 8/4 (2" thick) sizes at 8-10" wide by 16 feet in length with 1-side clear (1sc), or 2sc.

Please call ahead for availability of dimensional lumber.

Live Edge Timber

Dimensional Lumber

Dimensional Lumber

Most common rough-sawn lumber is offered Plain-sawn or Quarter sawn. Slab timber with or without a "live edge" are normally plain cuts or simply "flat" sawn.

Dimensional lumber boards can be milled as S3S or S4S. You can also bring your own log out to "The Mill" or call for a free estimate.

Click below on "Lumber Cost" to view a price list of lumber per/bf

Or download the pdf for a copy of our current price list.

(not yet available)

*Pricing subject to change without notice.

Custom Millwork

Dimensional Lumber

"Plain" or Flat Sawn

We can custom mill your lumber from logs that are available here at the mill site or any logs that you bring to us.

Custom milled lumber pricing are charged "per board foot" (p/bf) and may vary depending on what type of wood (hard or soft) and the type of cuts you desire.

Blade charges may apply.

"Plain" or Flat Sawn

"Plain" or Flat Sawn

"Plain" or Flat Sawn

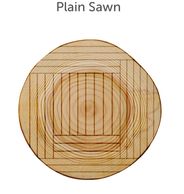

Plain-sawn (or Flat-sawn) lumber milling is the most common and economical for dimensional lumber with minimal product waste. The milling of the log results in lumber with annular growth rings intersecting the face of the board at 45 degrees or less (known as tangential plane). The face of the lumber often results in a "cathedral pattern.

Quarter Sawn

"Plain" or Flat Sawn

"Live Edge" Slab

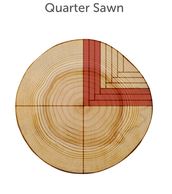

Quarter sawn wood has an amazing straight grain pattern that lends itself to design. Quarter sawn lumber is wood where the annular growth rings intersect the face of the board, slightly more perpendicular, at a 60 to 90 degree angle. Quarter sawn wood can produce a dramatic ray flecking in many types of hardwood specie.

"Live Edge" Slab

"Plain" or Flat Sawn

"Live Edge" Slab

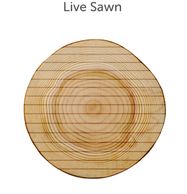

Live sawn or Slab cut timber, commonly known as "Live edge" Slab, is similar to Plain sawn cuts of lumber in which the log is cut straight down the radial of the log. The wood's tangential grains varies along the face of the board.

Lumber Price List Download

Information about Lumber Calculation and estimated Costs

How much will it cost?

All milled lumber costs are determined by a common lumber board foot (bf) calculation. This is not "rocket science"; Below is a simple explanation how it is determined. Understand, this calculation is for the volume of the lumber, not just the board's "linear" dimension in length (these have two different values).

I set my cost for lumber using a "volume" board foot (p/bf) calculation, along with the type of timber specie and its "hardness" of wood, and the type of milling process the the customer desires. These costs can be discussed in further detail with the customer prior to any milling orders being agreed upon.

A lumber board foot (bf) is a volumetric unit of measure calculated by multiplying the thickness (T) and width (W) of the lumber (measured in inches) by its length (L) (typically measured in feet), then divide by 12.

Click the "Lumber Cost" button below to review prices per board foot cost after you determine your total board foot measurement from the given examples below.

Review the example below to determine the size and cost of your lumber.

Determine your Board Foot measurement and estimated Cost for lumber:

Step 1:

(T) thickness (in.) X (W) width (in.) X (L) Length (ft)

12

*(If legnth of board is measured in inches, divide by 144)

Example: 2" x 8" x 8' Board

T x W x L = 2" x 8" x 8' = 10.66667 (Bf)

12 12

Example: 2" x 8" x 96" Board

T x W x L = 2" x 8" x 96" = 10.66667 (Bf)

144 144

Step 2:

Review or download the "Lumber Price List" (currently Not Available) pdf and multiply the price of the specific lumber you are looking to purchase and multiply that lumber cost (p/bf) by the total board feet you just calculated from the examples above. This should give you an idea of what your lumber will cost you.

The cost for "Green" lumber will differ (normally lower) than that of dried lumber. Pricing on available select slabs of hardwood can also vary depending upon the uniqueness and quality of the grain.

Can I bring my own logs or lumber?

Absolutely! Custom milling prices are usually charged per board foot (p/bf) or on an hourly rate. Custom milling costs may vary depending upon the specie of timber, and the type of sawing you desire.

Lumber milling Rate:

1. $130 per hour or by the board foot depending upon which is more economical.

2. Blade charges are usually estimated in the quote for saw milling services. Additional blades charges may apply at $40 per blade if necessary to complete the job or any unforeseen foreign metal debris in your log damages the blade beyond further use.

3. Some Millwork orders require a 50 percent deposit prior to the beginning of any services. This amount will be shown as "paid" toward the total charges when you receive your Millwork invoice order. Customers are encouraged to inquire about these costs prior placing and "accepting" their order.

Additional Fees that May Apply

Blade Replacement:

Blades used in custom milling of Timber for a customer may have a replacement charge of $40 per blade used, and additional blade charges may be accessed for the completion of the milling if any embedded foreign objects are struck within that Timber brought in by the customer, such as metal or rocks. Extremely muddy logs will cause a blade to become dull quicker and a blade charge may be added. Customers are responsible to reasonably remove excessive dirt and any foreign objects prior to dropping off their Timber for milling.

Pickup and Delivery Charges:

Pickup and delivery of logs or lumber is available at a mileage rate of $1.85 per mile.

Storing/Drying Milled Lumber:

Air-dry storage and Kiln drying for customer's lumber is based on "space available".

Air-drying Lumber and Storage charge is $1.00 p/bf for up to 30 days. This includes lumber "stickering" and stacking, protection from inclement weather under a covering during storage and open air-drying, and an application of insect controls.

Kiln drying charges are $1.75 p/bf for up to 45 days. This includes lumber "stickering" and stacking, an application of insect controls, and periodic moisture content checks. The customer is notified when an equilibrium MC is achieved and should arrange pickup or delivery of the dried product.

Please request for additional storage time if needed, but understand other customers may have already have reserved a storage space at the end of your storage time. I will try to fit as many folks in as possible for the time they need. We'll work it out.

What if You need more time?

Not a problem, but please arrange this in advance as there may be several folks also needing service and storage time and space is critical. Milling orders that are considered "small" I can usually fit them in between other orders and have your lumber ready in a short time, but please inquire ahead of time.

Also, please understand that all products milled by Sea Island Millworks that are agreed upon with the customer prior to any services and the delivery of product(s) being concluded, must be paid in full and received by the customer within 7 days of the completion date of your order. If this delivery date is unable to be met, the customer is responsible to notify Sea Island Millworks at least 24 hours ahead of the completion date. Otherwise, if the customer does not make these arrangements ahead of time, it may be likely and most unfortunate that the customer would forfeit their lumber product to the ownership of Sea Island Millworks, LLC. So, please call me ahead of time and we'll figure something out. Thanks